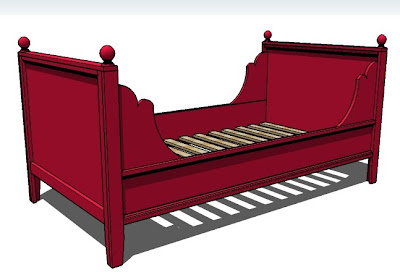

This beautiful daybed will surprise you with it's easy to build plan. Features scalloped edges, moulding on the inside and out and finials. Easy to modify to a full size.

WHAT YOU CAN'T BUY As you probably know, Pottery Barn used to sell a beautiful Priscilla Dayed, but the bed is discontinued. And I have for years wanted to redesign the bed, to make in "buildable." And today, I think I have.

DREAMING OF THIS BED After putting together the post for the Swedish planked bed, then putting Grace to bed, I dreamed about scrolling with a jigsaw and using a Kreg Jig to build this bed. Because the major issue before having a Kreg Jig in my tool belt was connecting the beautiful scalloped corners to the side rails. Now we can easily do that!

IT'S EASIER THAN IT LOOKS Please don't let this bed intimidate you. If a jigsaw doesn't intimidate you, you, yes YOU, can build this bed. It's amazingly easy. For the trim, we are going to use store bought moulding, and then for the finials . . .

FINIALS? YEAH, WE'VE GOT A HACK FOR THAT For the finials, simply pick up a four curtain rod finials next time you are out shopping (unfinished preferred, but if you are painting, a spray coat of primer can get these babies ready for your bed). It will be easy to drill a simple hole on the tops of your daybed tops and screw these in.

Go ahead, click for a larger view. It's much easier than it looks, eh? Now I'm just going to put this out there, since I know most of you are Moms just like me. If you can figure out how to raise a baby, if you took a baby home from the hospital and the baby not only survived, but they thrived, then you can do this. This is NOTHING compared to the major project of raising kids. You've got the ability. Let's get building!

Preparation

- 6 – Pieces of 2 1/4″ moulding, 8′ Length

- 2 – 1×10, 8′ Length

- 1 – Sheet of 3/4″ MDF or plywood

- 4 – 1×2 Boards

- 11 – 1×3 Boards

- Wood Filler

- Wood Glue

- 1 1/4″ Nails

- 2″ Nails

- 1 1/4″ Screws

- 2 – 3/4″ plywood @ 40 1/2″ x 27″ (Panels)

- 4 – 1×2 @ 34 1/2″ (End Legs, ends tapered in step 1)

- 2 – 1×3 @ 37 1/2 (Bottom Panel Trim)

- 4 – 1×3 @ 34 1/2″ (Side Legs, ends tapered)

- 2 – 1×3 @ 42″ (Top of Ends)

- 2 – 2 1/4″ Base Moulding @ 37 1/2″ (Trim for outside of panel)

- 2 – 2 1/4″ Base Moulding @ 40 1/2″ (Trim for inside of panel)

- 4 – 3/4″ MDF @ 15″ x 15″ (Scalloped Sides)

- 2 – 1×10 @ 75″ (Siderails)

- 2 – 1×2 @ 75″ (Cleats)

- 14 – 1×3 @ 39″ (Slats)

- 4 – 2 1/4″ Moulding @ 73″ (Siderail Trim)

You can click any of the images for a larger view. Work on a clean level surface. Be careful as you are working with a nailer. Check for square and level after each step. When nailing into MDF, avoid fastening too close to the edges on the end grain side (practice on a piece of scrap MDF first). Use glue and be safe. BUILDING THE BED FOR NATURAL WOOD FINISH This bed is designed to be painted. You can create a stainable bed by using A1 plywood for the panels and joining two 3 – 1×6 @ 30″ together, then cutting the panel in half to get two panels, approximately 15″ x 16 1/2″ (use a Kreg Jig™ to join the panels). Then cut your scalloped shape from these panels. Do not attempt to iron on edge banding to the scalloped edges and use plywood, you will not be able to get your iron in the scalloped parts. You will also need to purchase wood moulding instead of primed MDF moulding.

Comments

kda

Tue, 03/29/2011 - 19:18

I want this for my sun

I want this for my sun room!! I love it!!

Lady Goats

Thu, 04/14/2011 - 10:25

Can this be modified for a trundle?

I've been looking at this for days to try to come up with ways this could be modified to fit a trundle. I know I can add height, but I need to make the width between the legs wider. I was trying to find a way to make the 1x3 legs 1x2s (which would require the mdf to be 1/2 or thinner - and I don't even think that would be enough room). ANY ideas?!

rapunzel

Thu, 09/01/2011 - 00:10

Add a back? Tried to post this before, but I don't see it here.

Can anyone help me with instructions for adding a back to this bed? The bed will stand in front of curtains, and I'd like to be able to pile cushions against the back so that my guest can use it as a sofa for TV-watching before dinner.

Thanks!

Mona (not verified)

Tue, 04/03/2012 - 08:02

Queen Size Modifications

Hello,

I really, really, really want to make this but was wondering if anyone has made this for a queen size bed. If so, what are the measurements for the queen?

This is super cute and would match my style to a t!

Thank you,

-M

ellen (not verified)

Tue, 04/03/2012 - 14:37

This is really wonderful! I

This is really wonderful!

I think that we (mostly my hubby) might be able to modify this so that we can use a vintage (62 year old) crib that my sister, myself, her daughter, my son and her visiting grandchildren have used.

I want to save parts of the crib, notably the head and food boards for the graphics and for the family history.

Thank you for the wonderful idea!

Ellen

Patsy (not verified)

Fri, 07/06/2012 - 21:01

Lydia twin daybed

I too, love this bed. I would like to try to make it for my grand-daughter. My husband said, "Are you trying to be a carpenter?" He doesn't think I can do it. My daughter and I are going to do it and show him :)

Question: how are the side rails attached? I didn't see instructions for pocket holes.

Thanks so much. I love your videos too. I'm so impressed!

shelli (not verified)

Thu, 07/19/2012 - 14:17

Lydia

What is the approximate cost to build this bed?

In reply to Lydia by shelli (not verified)

Lady Goats

Thu, 07/19/2012 - 16:45

Lydia

I built the bed and trundle for $100.

Lori Feltner (not verified)

Tue, 10/09/2012 - 17:55

Hardwood Version

I've decided that I will be making two of your designs and I have a question pertaining to the Lydia Daybed.

BUILDING THE BED FOR NATURAL WOOD FINISH

This bed is designed to be painted. You can create a stainable bed by using A1 plywood for the panels and joining two 3 – 1×6 @ 30″ together, then cutting the panel in half to get two panels, approximately 15″ x 16 1/2″ (use a Kreg Jig™ to join the panels).

My question is in your above statement "two 3 - 1x6 @30"

I get the 30" and the 1x3, but what is the other part trying to tell me?

Also, I'm building this bed for a 'larger' member of my family, how can I beef it up without getting frustrated?

Charlinn

Sun, 03/24/2013 - 21:32

Awesome!

Perfect! This is exactly what I was looking for to make for my daughter! Thank you so much! You rock!!

thomatuttle

Thu, 05/23/2013 - 23:17

1x3's question

so, i went on home depots website so that i could kind of price out how much it would cost to make the bed. it wasn't too bad, until i came to the 11 1x3's. what length should they be (or is there a standard size and i just don't know because i'm new to the whole woodworking thing). also, there was a major price difference between using 1x3 poplar boards and using 1x3 furring strips. using 1x3 poplar boards added about $100 on to the cost. are furring strips what most people have used?

Tosca

Thu, 06/13/2013 - 09:26

Metric

I would love to make this bed but I live where we use metric. I see someone has converted the measurements to metric. Please could you help me withthis? I love your site Ana. Thank you from Tosca in sunny South Africa